Ultimate Guide to MEP Systems in Construction

12/22/2022

Ultimate Guide to MEP Systems in Construction

In today’s buildings, complex systems coexist with robust structures. Teams from several disciplines must work together to ensure aesthetics, security, ease and efficacy. Mechanical, electrical and plumbing (MEP) engineering includes some of those systems. The MEP services market in the U.S. reached a value of $32.79 billion in 2020 and may reach $54.02 billion by 2026.

Additionally, efficient MEP design services must emphasize resource optimization and waste minimization due to the increasing trend toward sustainability in high-rise buildings. The global value of investments in energy-efficient buildings reached a new high in 2022.

Learn more about MEP engineering, different system and drawing types, and the role of MEP engineers in this complete guide.

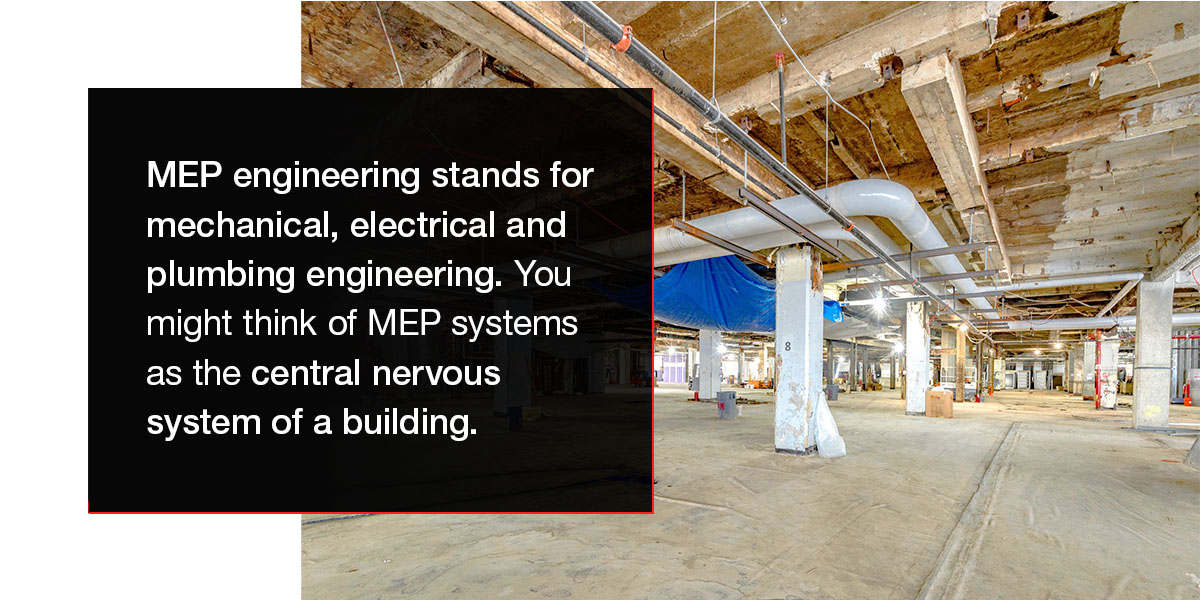

What Is MEP Engineering?

MEP engineering stands for mechanical, electrical and plumbing engineering. You might think of MEP systems as the central nervous system of a building. These three technical disciplines are typically combined and designed together as they have a high degree of interaction. This combined approach improves efficiency during design and construction. Together, these three systems create more comfortable building interiors.

MEP engineering is the science and art of planning, designing and managing the construction of a building’s MEP systems. These systems are responsible for a structure’s “creature comfort” qualities. MEP engineering makes buildings enjoyable and liveable, whether a single-story house or a 50-story skyscraper. MEP engineers create the pleasant indoor environments we all appreciate.

What Are the Different Types of MEP Systems?

Let’s take a deeper look at the three types of MEP systems to see how they’re often included in a project plan, resulting in a harmonious collaboration.

Mechanical Engineering

Mechanical systems include many components. However, heating, ventilation and air conditioning (HVAC) systems account for most mechanical design work in residential and commercial buildings. Mechanical design elements help make life inside a building more comfortable by regulating the indoor temperature and humidity levels. These systems also supply fresh air into the building to keep air pollutants low. Mechanical designing includes determining the best routes for heat distribution systems — like air ducts, hydronic pipes, refrigerant lines and steam piping.

Electrical Engineering

An electrical system powers more than a building’s lights. Electricity keeps devices powered, alarm systems running and other systems functional. HVAC systems require mechanical and electrical engineers to work closely together. Finding the best paths for electrical conduit and wiring in high-rise buildings may save a lot of material. Engineers plan out conduit and wiring using MEP design software to limit overall circuit length and avoid site conflicts with mechanical and plumbing installations.

Plumbing Engineering

Plumbing systems are crucial as they provide fresh drinkable water and safely carry sanitary water and stormwater away. Plumbing installations interact with mechanical and electrical systems in various areas, so cooperation between design teams is essential. Plumbing engineering consists of arranging piping routes and conduits in electrical design. MEP engineers use sophisticated tools to simplify the process and eradicate disputes.

What Are the Types of MEP Drawings?

Building MEP systems are crucial in ensuring effective building planning and performance, and high-quality and accurate MEP drawings are vital. There are various types of MEP drawings, each with a different purpose.

Penetration drawings

An MEP system will penetrate the building’s numerous wall and floor areas. Penetration drawings guarantee precisely positioned apertures and include the necessary dimensions for the component to receive clearance. They’re also needed to maintain the structural integrity of the building so the design cuts don’t cause any future problems.

Detailed shop drawings

Many MEP components require pre-fabrication — like ducting, custom plumbing connections and air-handling systems. Detailed shop drawings illustrate the fabrication and installation of these components and ensure parts created off-site can be fitted on-site without difficulties.

Pipe spool drawings

These drawings depict a single spool and provide all the information a fabrication facility needs to produce or assemble it. It includes items like the cut length of the pipe; the number, kind and position of each weld; and a parts list of all the fittings.

Coordination drawings

Engineers keep MEP systems from colliding with coordination drawings, which provide a clear action plan. These drawings aid in detecting obstacles created by interacting MEP systems before the installation starts — saving time, resources and labor.

As-built drawings

For documentation and facility management purposes, as-built drawings are highly beneficial for remodeling and fit-out projects. These drawings account for modifications made throughout the building phase and offer information on the precise position of MEP components.

Roles of MEP Engineers

MEP engineers play a role in each stage of the construction process. They’re responsible for planning, designing and managing MEP practices and developing standard MEP policies. The construction sector requires a high level of precision, competence and safety from MEP engineers to ensure construction projects run smoothly and successfully. MEP engineers should have the following characteristics:

- Responsive character: MEP engineers must be quick to respond to any challenges and rapidly provide solutions and feedback. A building’s infrastructure contains interconnected components, and one problem often affects multiple systems, requiring instant solutions.

- HVAC expertise: HVAC is an essential component of every building project. Engineers need substantial competence in creating efficient, effective and environmentally friendly solutions to guarantee a seamless outcome.

- Electrical expertise: When it comes to electrical connections and lighting, MEP engineers must check every aspect thoroughly to verify all connections are safe, secure and precisely positioned.

- Plumbing expertise: The MEP engineer is responsible for using energy-efficient connections, reducing waste and using appropriate technology and materials to design and install plumbing networks.

- Understanding of energy management: MEP Engineers should stay up to speed on energy-efficient standards and propose solutions to projects based on their size and scope. This contributes to energy conservation, lower building costs and a lower carbon footprint.

- Fire safety expertise: A properly functioning fire alarm is essential to fire safety. Fire alarm systems must fulfill a project’s requirements and industry standards. Identifying at-risk locations requires careful planning and installation.

Why MEP Is Important in Buildings

When planning building systems, an integrated MEP approach outperforms developing each system separately. An isolated design process complicates coordinating interactions across building systems, and equipment position disputes are frequent. MEP engineering is essential in buildings for several reasons.

MEP engineering is a form of sustainable construction, making buildings more energy efficient and reducing carbon dioxide emissions. Because commercial buildings emit greenhouse gases from cooling, heating and energy, MEP employs effective HVAC frameworks, reduces overall water and energy consumption and embraces dynamic building designs — upgrading the base of building designs.

)